Thermal Energy Harvesting: The Silent Power Revolution in Wearables

In an era where our devices constantly demand more power, an overlooked technology is quietly transforming how our gadgets stay charged. Thermal energy harvesting – converting waste heat into usable electricity – is emerging as a game-changer for wearable technology. This approach leverages the temperature difference between your body and the surrounding environment to generate power, potentially eliminating the need for conventional battery charging in some applications. As major tech companies invest in this technology, we're witnessing the early stages of what could become a fundamental shift in how we power our personal electronics.

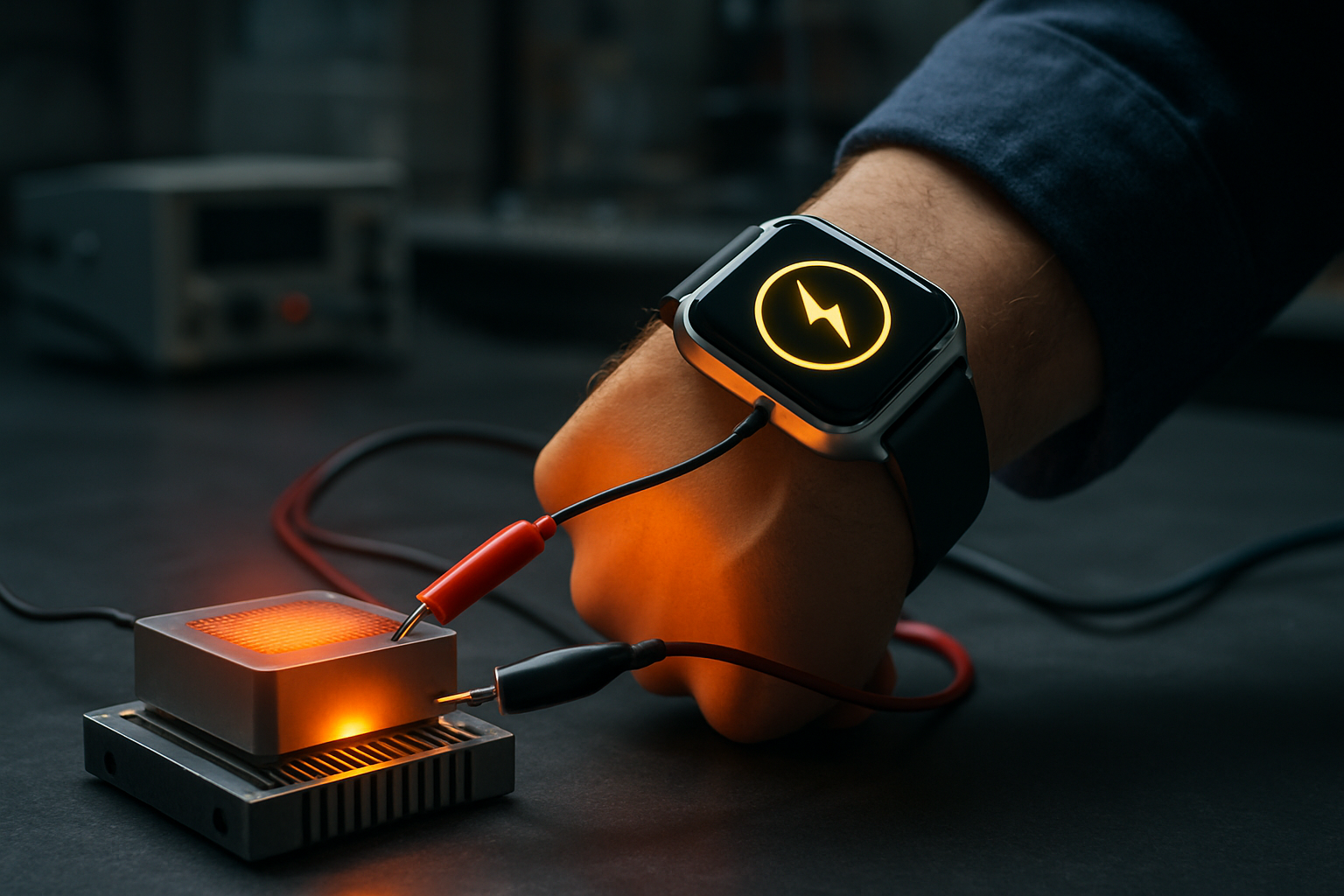

How Body Heat Becomes Electricity

The science behind thermal energy harvesting centers on the thermoelectric effect, discovered nearly two centuries ago but only recently becoming practical for consumer electronics. When there’s a temperature gradient across certain materials, electrons flow from the hot side to the cold side, generating an electrical current. In wearable applications, your body serves as the heat source (typically 98.6°F), while the ambient air acts as the heat sink.

Modern thermal energy harvesters use semiconductor materials arranged in arrays of tiny thermocouples. These components amplify the small voltage generated across each temperature differential point. While traditional thermoelectric materials like bismuth telluride have been around for decades, recent advancements in nanomaterials have dramatically improved conversion efficiency – the critical metric that determines how much of that thermal energy actually becomes usable electricity.

The most advanced thermal harvesting materials now achieve conversion efficiencies approaching 8-10% in laboratory settings, a significant improvement from the 1-2% common just a decade ago. This efficiency jump is what’s finally making the technology viable for consumer applications.

Current Market Applications

Several companies are already implementing thermal harvesting in commercial products, though most remain niche offerings. Matrix Industries (now Aireon) pioneered this space with the PowerWatch, a smartwatch that never needs charging as long as you’re wearing it. While initially limited in features compared to mainstream smartwatches, the latest iterations incorporate increasingly sophisticated capabilities while maintaining their signature battery-free operation.

Garmin has incorporated similar technology in some of their outdoor GPS watches, using thermal harvesting as a supplementary power source that extends battery life rather than eliminating charging entirely. This hybrid approach represents the most practical implementation in today’s market – thermal harvesting works alongside conventional batteries rather than replacing them entirely.

Beyond timepieces, thermal energy harvesting has found applications in medical devices. Continuous glucose monitors and heart rate sensors that require constant operation benefit significantly from this technology, as they maintain direct contact with the skin and therefore access to a consistent thermal gradient. Companies like Abbott and Medtronic are actively researching integration of thermal harvesting into their next-generation medical wearables.

Most thermal harvesting devices currently retail between $200-500, positioning them as premium products. However, as manufacturing scales increase and the technology matures, industry analysts expect prices to decrease substantially over the next five years.

Technical Challenges and Limitations

Despite its promise, thermal harvesting faces significant challenges before widespread adoption becomes realistic. The most fundamental limitation is the modest power output – current commercial implementations typically generate between 10-100 microwatts per square centimeter of harvesting material. This output is sufficient for low-power applications like basic sensing and data transmission but inadequate for power-hungry features like high-resolution displays or cellular connectivity.

Environmental conditions also dramatically impact performance. The technology requires a sufficient temperature differential to function effectively. In hot environments where ambient temperature approaches body temperature, power generation drops significantly. Similarly, if the device isn’t making good contact with skin, power production suffers.

Material durability presents another obstacle. Thermal harvesting components undergo continuous expansion and contraction due to temperature fluctuations, potentially leading to mechanical fatigue and performance degradation over time. Manufacturers must balance durability with flexibility, especially for devices meant to be worn comfortably for extended periods.

The Next Generation: Flexible and Fabric-Based Systems

The most exciting developments in thermal harvesting involve integration directly into textiles. Researchers at MIT, Stanford, and several tech companies are developing threads and fabrics with thermoelectric properties that can be woven into clothing. These materials maintain normal textile properties – flexibility, washability, and comfort – while generating small amounts of electricity from body heat.

Imagine workout clothes that power your fitness tracker, jackets that can charge your smartphone, or medical garments that power health monitoring systems without external batteries. Early prototypes demonstrate that a thermal-harvesting shirt could potentially generate 1-2 milliwatts during normal activity – enough to power small sensors and transmit data wirelessly.

Japanese textile manufacturer Teijin has already unveiled prototype garments incorporating thermal harvesting elements, while Under Armour and Adidas have filed patents suggesting similar technology may appear in upcoming athletic wear. Industry analysts project the first mainstream thermal-harvesting garments could hit the market within 3-5 years, likely commanding a 30-50% premium over standard apparel initially.

Integration with Other Energy Harvesting Technologies

Perhaps the most promising approach isn’t thermal harvesting alone, but its combination with other ambient energy collection methods. Researchers are developing hybrid systems that combine thermal harvesting with kinetic energy (from movement), solar cells (for outdoor use), and RF energy harvesting (capturing ambient radio waves).

These multi-modal energy harvesting systems create redundancy – when one energy source is unavailable, others can compensate. A wearable might generate power from body heat while indoors, switch to solar when outside, and supplement both with energy from movement throughout the day.

Samsung’s research division recently demonstrated a prototype wristband incorporating three harvesting technologies that generated consistent power sufficient for basic health monitoring functions without requiring traditional charging. Similarly, Google’s Project Jacquard has expanded beyond touch-sensitive fabrics to explore integrated energy harvesting solutions that could power their smart textile interfaces.

As these technologies mature and converge, we’re approaching a tipping point where our relationship with device charging could fundamentally change – not through revolutionary new battery chemistries, but through cleverly harvesting the energy that surrounds us every day.