Variable Compression Ratio Engines: The Next Frontier in Combustion Efficiency

In a world obsessed with automotive innovation, one technology stands at the crossroads of tradition and progress. Variable compression ratio engines represent an engineering marvel that optimizes performance without abandoning the internal combustion legacy. While manufacturers race toward electrification, this mechanical breakthrough allows conventional engines to achieve remarkable efficiency gains through real-time adjustment of their fundamental operating parameters. The technology addresses the age-old compromise between power and efficiency by dynamically altering how the engine breathes and burns fuel. As automotive landscapes evolve, this adaptive approach to engine design might prove to be among the most significant advancements for extending the relevance of combustion powertrains in an increasingly restrictive regulatory environment.

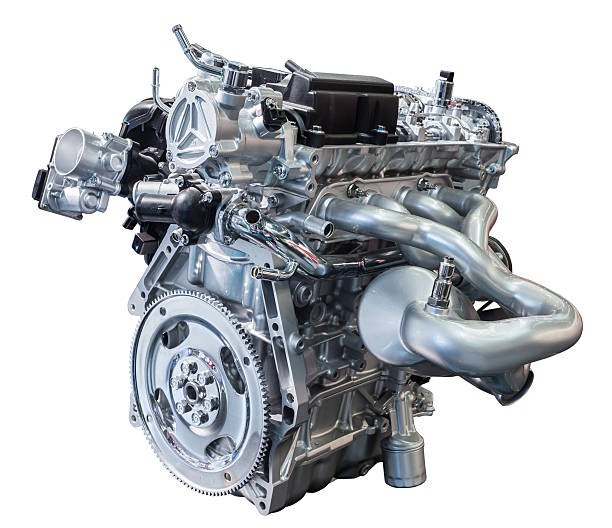

The Mechanical Magic Behind Variable Compression

At its core, a variable compression ratio engine can dynamically alter the volume relationship between the combustion chamber at its largest and smallest points. Traditional fixed-ratio engines force engineers to choose a single compression ratio—typically between 8:1 and 14:1—that represents a compromise between performance and efficiency. This one-size-fits-all approach means the engine never truly operates at its optimal state across different driving conditions.

Variable compression systems employ several ingenious mechanisms to overcome this limitation. Some use movable cranks that can adjust the piston’s top-dead-center position, effectively changing the combustion chamber volume. Others utilize connecting rods with adjustable lengths or multi-link systems that can alter the geometric relationship between piston movement and crankshaft rotation.

The most commercially successful system to date comes from Infiniti/Nissan, whose VC-Turbo technology uses an elliptical actuator connected to a harmonic drive that can continuously adjust the connecting rod’s effective length. This allows the engine to seamlessly transition between compression ratios of 8:1 for high performance and 14:1 for maximum efficiency—all while driving.

Historical Journey to Variable Compression

The quest for variable compression technology spans nearly a century, with early patents appearing in the 1920s. Saab made significant strides with their SVC (Saab Variable Compression) prototype engine revealed in 2000. This innovative design used a tilting cylinder block relative to the crankshaft to modify compression ratios, but manufacturing complexities prevented production.

FEV Engine Technology developed a different approach in the early 2000s, creating a system using a secondary piston to alter the combustion chamber volume. Meanwhile, MCE-5 in France developed a sophisticated rack-and-pinion system that could adjust compression ratios with remarkable precision.

Despite these admirable efforts, the technology remained largely conceptual until 2018, when Infiniti introduced the first mass-produced variable compression engine in the QX50 SUV. This milestone marked the transition from engineering curiosity to commercial reality, demonstrating that the complex mechanical systems required could indeed be manufactured at scale and with sufficient reliability for everyday use.

Performance Benefits Beyond Fuel Economy

While improved fuel efficiency remains the headline benefit—with gains typically ranging from 10-15% compared to fixed-ratio counterparts—variable compression technology delivers several other significant advantages. The most immediate is the elimination of the performance-efficiency compromise that has constrained engine designers for decades.

At high compression settings, these engines achieve greater thermal efficiency, extracting more energy from each fuel molecule during normal cruising. When power demands increase, the system can rapidly switch to lower compression ratios to accommodate higher boost pressures without detonation issues, essentially providing two engines in one.

This adaptability also produces a notably flatter torque curve. Traditional turbocharged engines often struggle with low-end torque before the turbocharger spools up—the dreaded turbo lag. Variable compression systems can mitigate this effect by running higher compression at low RPMs, improving off-the-line acceleration and throttle responsiveness while maintaining fuel economy benefits.

An often-overlooked advantage is emissions reduction. By operating at optimal compression for each driving scenario, these engines produce fewer unburned hydrocarbons and nitrogen oxides. The ability to run higher compression ratios during light loads means more complete combustion, addressing one of the persistent challenges of meeting increasingly stringent emissions standards without sacrificing performance.

Engineering Challenges and Complexities

Implementing variable compression technology presents formidable engineering obstacles. The systems must withstand enormous forces while maintaining precise control over mechanical tolerances under extreme temperature variations. This balancing act requires advanced materials and manufacturing techniques that have only recently become economically viable for mass production.

Reliability concerns have dogged development efforts for decades. Early prototypes suffered from durability issues as the additional moving parts introduced potential failure points. Modern implementations have largely overcome these challenges through extensive testing and refinement, but the added complexity still raises questions about long-term durability compared to conventional fixed-ratio engines.

Control systems represent another significant hurdle. The engine management computer must precisely coordinate compression changes with ignition timing, fuel delivery, and turbocharger boost pressure—often making adjustments hundreds of times per minute. This requires sophisticated sensors, actuators, and algorithms that can respond to changing driving conditions without creating drivability issues or hesitation.

The cost impact cannot be overlooked. The additional mechanical components and control systems add approximately 10-20% to manufacturing costs compared to conventional engines of similar output. This premium poses challenges for mass-market adoption, particularly in price-sensitive segments where the efficiency gains may not justify the increased purchase price for budget-conscious consumers.

Market Adoption and Future Prospects

Despite the compelling benefits, market penetration for variable compression technology remains relatively limited. Beyond Infiniti/Nissan, most major manufacturers have explored the concept but have been hesitant to commit to mass production. This reluctance stems partly from the substantial investment required to retool production lines and partly from uncertainty about consumer willingness to pay a premium for incremental efficiency gains.

The technology faces intensifying competition from alternative powertrains, particularly as battery costs decline and charging infrastructure expands. Manufacturers must weigh the substantial development costs against the potentially limited lifespan of internal combustion technology in an increasingly electrified landscape.

However, several factors suggest variable compression may yet gain wider adoption. The technology provides an intermediate step that can help manufacturers meet increasingly stringent fleet emissions targets while electric vehicle technology matures. For markets where charging infrastructure remains underdeveloped or for applications where battery weight poses significant disadvantages, these advanced combustion engines offer a compelling compromise.

The future may see variable compression technology combined with other innovations like cylinder deactivation, advanced thermal management, and sophisticated exhaust treatment systems to create highly efficient combustion engines. These could serve as range extenders in plug-in hybrids or as primary power sources in markets where pure electric vehicles remain impractical due to infrastructure limitations.

The Bridge Between Past and Future

Variable compression ratio engines represent more than just an incremental improvement to century-old technology—they embody a fusion of mechanical ingenuity and digital control that extends the viability of internal combustion. While the automotive world increasingly embraces electrification, these sophisticated powertrains remind us that innovation remains possible even within mature technologies.

The true significance of variable compression may ultimately be as a bridge technology—allowing manufacturers and consumers to transition gradually toward zero-emission vehicles while continuing to refine the driving experience. By addressing the fundamental limitations that have constrained engine efficiency since the earliest days of automotive development, these systems demonstrate how creative engineering can breathe new life into established principles.

As regulations tighten and consumer expectations evolve, variable compression engines represent one of the most promising paths for extending the relevance of internal combustion. Whether they become widespread or remain a niche technology may depend less on their technical merits and more on broader market forces and regulatory directions. Either way, they stand as testament to the remarkable ingenuity of automotive engineers determined to extract maximum performance from every drop of fuel.